February 27, 2025

PTD received 'Best Employee Accommodation Management and Maintenance ' from ALBA CEO for the year 2024, Post various audits from ALBA Team

October 16, 2024

Power Tech Group is now ISO 14001 Certified , along with the previously held ISO 9001 and ISO 45001 Certification, Recently we completed the Integrated Management System Audit for all 3 certifications and got certified

August 11, 2024

PTD Successfully completed GT T1C Nozzle Replacement Mitsubishi works for ALBA Block 4 Expansion Project and received a letter of Appreciation for our support and completion of the Project from MHI Team.

July 28, 2024

PTD has secured 3 Year long term contract with ALBA Power Station 5 for Mechanical, Electrical and Instrumentation Department.

December 21, 2022

Power Tech Group is happy to share that our company has been awarded a Silver EcoVadis Medal. This result places our company among the top 25 percent of companies assessed by EcoVadis.

November 30, 2022

PTD Successfully Completed GT Major Outage with NMES (ACWA POWER) for the NOMAC ALDUR-II Plant, PTD Also completed Unplanned GT-12 Outage in ALDUR-1 for AEOM

April 15, 2022

Power Tech recently completed GPIC Turnaround 2022 in Bahrain, providing close to 100 resources from Instrumentation, Electrical and Mechanical Stream

Meet our Leadership Team

Mr. S. A. MOHAMED SULTAN

Managing Director - Power Tech Group Companies

Mr. A. MOHAMMED SHEIK RAJA

General Manager- Power Tech Group Companies

Mr. AHMED IBRAHIM

General Manager - Global Powertech UAE

Mr. J. MOHAMED JASIM

Manager- Power Tech Group Companies

Hakkim Mohamed Ibrahim

Deputy General Manager - SamTech KSA

WE SERVE GLOBALLY

Our Global Presence

Power Tech Group Companies an ISO 9001 and ISO 45001 company is Unique in Indian sub-continent and GCC countries, as ONE-STOP-SHOP for total power plant services in the areas of Repairs & Retrofits, EPC contracts, O&M contracts, Re-Engineering and Relocation of Power Plants, Spares & Services for a decade. We offer Qualitative and Economical Alternative to various OEMS around the World in the areas of expertise. We offer quality services and expertise in Repairs & Retrofits, Spares & Services, EPC contracts, O&M Contracts, Re-Engineering and Relocation of Power Plants, for a decade.

0

Years

0

Countries

0

Customers

Valve Services - Human Resource

& Manpower Supply

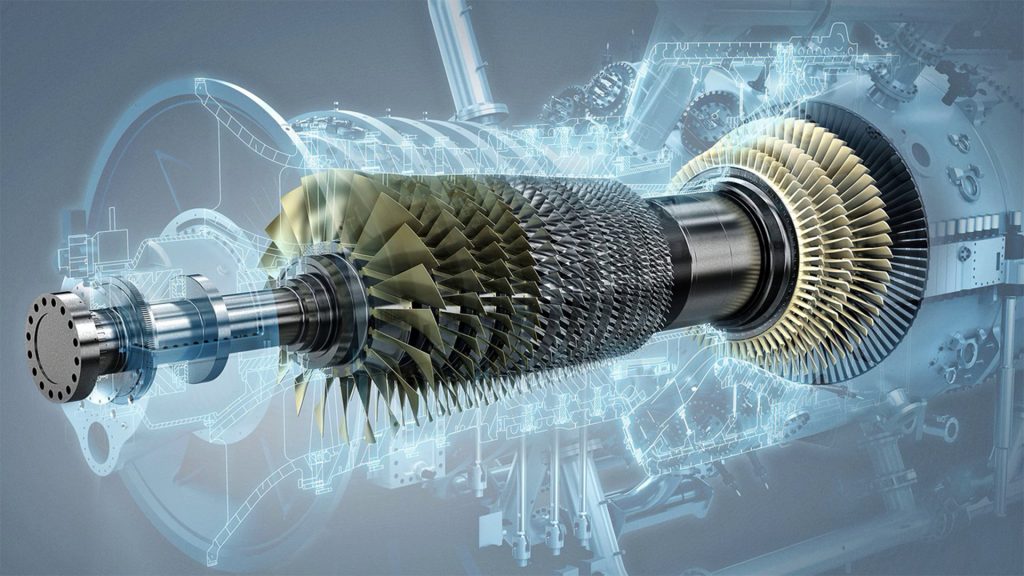

Gas Turbine Services

We undertake capital overhauls of Turbo generator, Turbo compressor, Gas Turbines, assess present condition, identify defects, future failure predictions and improve the efficiency of equipment.

PTD has experienced crew Specialized in GT and ST works, having rich experience GT Major, Minor, Combustion Inspection, Turbine Hot Gas Path Inspection, GT Upgrade, Crew having complete exposure to GE, Siemens and ALSTOM turbines

To know more Click HereSteam Turbine Services

Based on our vast Steam turbine knowledge Power Tech Development offers its Services for any Impulse or Reaction steam turbine, regardless of manufacturer and application Our Steam Turbine Team offers servicing of specific components to overall steam turbine health solutions.

Our portfolio of developed steam turbine solutions, reverse engineering capabilities and steam turbine spare parts packages cover major fleets from Operations and maintenance to performance and lifetime improvement.

Upgrades : Our integrated approach allows us to find the ideal solution for your plant, budget, and strategy. Steam turbines upgrades not only help extend the life of the turbine but also improve overall steam turbine performance

Maintenance and Repairs : Power Tech Development can provide quick and effective Steam Turbine Engineering services to any location. Steam turbine maintenance teams leverage specialized tools and technicians to assist with repairs from rotors to blading.

Parts : For complete steam turbine overhaul service we offer standard and tailor-made parts for all types of steam turbines. PTD uses precisely fabricated parts to replace steam turbine components, address issues and increase the life of a steam turbine power system.

To know more Click HereOperation and Maintenance

Power Tech Development is having more than a decade experience in doing Gas Turbine Maintenance and Steam turbine maintenance projects, Boiler Maintenance and also providing Quality Technical Manpower for Operation and Maintenance to various plants across GCC Countries

Our Esteemed Client List- Huge Market Share in the Power Plant and Oil & Gas Industry

Online/Offline Safety Valve Testing & Calibration

THE ONLY THING MORE IMPORTANT THAN A SAFETY VALVE IS HOW YOU TEST IT”

AccuTEST Safety Valve Test System- Online Safety Valve Testing

Test online

Safety valves are essential to the protection of lives and property, so regular testing is crucial to ensure that valves are functioning properly. But can you really be sure of the results if the test is not conducted under the stress of everyday conditions? Unsurpassed for accuracy, reliability and safety, the advanced technology of AccuTEST was developed to test safety valves while in position, under a full load, for consistently superior, reproducible results

Advantages

- Totally automated operation, battery operated motor battery life under normal usage.

- Set pressures automatically calculated by measuring lift force, line pressure and acoustic trigger

- Universal mounting assembly ensures use on all types of exposed spindle valves.

- Easy one-handed mounting with innovative iris plate and self-aligning spindle adapter.

- Full range of spindle adapters available in metric, coarse and fine threads

- No hydraulics, cylinders, or hand jack.

- Lightweight, compact design for portability in the plant.

- Load rig allows for lift forces up to 4,500 kg (10,000 Ib)

Boiler Maintenance and Commissioning

Online leak sealing today is the leak-sealing solutions of choice as it saves energy, prevents and expensive and unwanted shutdown and can address a wide variety of leaks. With the combination of engineering solutions support from global experts, we have leak sealing compounds that can address a wide variety of steam, chemical, hydrocarbon and gas leaks at temperature up to 700° C. We have highly trained, highly skilled technicians who can handle the adverse situations very tactically and bring downs the situation to normal conditions.

Services we provide

- Boiler Installation and Commissioning

- Boiler Re-Tubing

- Boiler Maintenance and Servicing

- Inspection Testing and Calibration of Safety Valves .

- Have completed various projects with EWA , Power plants and across Industries

Heat Exchange Desing Commisiion and Maintenance

A heat exchanger is an apparatus where the exchange of heat energy occurs between two different fluids at different temperatures.

The most used is what is known as “tubular beam and cloak exchanger “, as its large surface structure allows to exchange large quantities of heat.

This type of exchanger has a cylindrical shape, formed by a container called the mantle, where a bundle of tubes passes through each of them, both of which are crossed by the fluids.

Power Tech has the executed various projects of Design and commissioning of Heat exchangers across various industries and also carried out maintenance of the same,

- Tube Bundle extraction.

- Re- Tubing or cleaning of the existing bundles.

- Insertion of the Bundles.

- Hydro Test and handover.

Online Leak Sealing & Hot Tapping Services

Online leak sealing today is the leak-sealing solutions of choice as it saves energy, prevents and expensive and unwanted shutdown and can address a wide variety of leaks. With the combination of engineering solutions support from global experts, we have leak sealing compounds that can address a wide variety of steam, chemical, hydrocarbon and gas leaks at temperature up to 700° C. We have highly trained, highly skilled technicians who can handle the adverse situations very tactically and bring downs the situation to normal conditions

Power Tech has combined with SYLMASTA to offer one of the kind unique Repair kits which can be used for the sealing solutions.

Fixing a burst or leaking pipe has never been easier thanks to the SylWrap range of leak repair products.

Repairs can be carried out to pipes of all materials and diameters in under 30 minutes without the need for any formal training. Each product comes with full instructions explaining how it should be used; simply follow those and your leaking pipe can be fixed in not time at all.

Sylmasta pipe repair products are used in both small domestic plumbing jobs and large scale industrial repairs. Sylmasta count several of the United Kingdom’s water companies among their regular users and have also supplied solutions to desalination plants, wastewater treatment works, nuclear power stations, pumping stations, petrochemical plants, quarry wash plants, freight ships and dry risers

To know more Click HereHot Tapping

When Hot Tapping Makes the Difference: Minimizing Disruption and Maximizing Efficiency

In the world of pipeline management, efficiency and minimal disruption are key. That's where hot tapping comes in, a specialized technique that allows you to connect to existing pipelines without interrupting the flow. This blog post dives into the benefits of hot tapping and the scenarios where it shines.

Uninterrupted Operations: Imagine needing to upgrade your pipeline system. Traditionally, this would mean shutting down the entire operation, resulting in lost production, frustrated customers, and significant financial losses. Enter hot tapping. This innovative method lets you seamlessly add new branches or isolate sections for maintenance all while the pipeline remains active. It's like performing surgery on a running engine – a feat of engineering brilliance.

Safety and Environmental Benefits: Beyond avoiding costly downtime, hot tapping also prioritizes safety and environmental responsibility. By eliminating the need for depressurization, the risks associated with handling highly pressurized systems are significantly reduced. Additionally, hot tapping minimizes product loss and prevents harmful gas emissions, making it a sustainable choice for your business and the planet.

Cost-Effective Efficiency: Let's talk numbers. By eliminating the need for lengthy shutdowns and complex rewelding procedures, hot tapping offers tangible cost savings. Less planning, reduced manpower requirements, and faster project completion times all add up to a more efficient and financially advantageous solution.

But Is Hot Tapping Always the Answer?

While hot tapping boasts impressive advantages, it's crucial to acknowledge that it's not a one-size-fits-all solution. This complex procedure requires extensive expertise and specialized equipment. Therefore, it's essential to carefully evaluate your specific needs and consider alternative methods before making a decision. Hot tapping thrives when:

- Shutting down the pipeline is impractical or financially detrimental.

- Minimizing downtime and maintaining operations is paramount.

- Safety and environmental considerations are high priorities.

Conclusion

Hot tapping is more than just a fancy technique; it' s a game-changer in the world of pipeline management.By prioritizing efficiency, safety, and sustainability, it offers a clear advantage for maintaining and upgrading your system with minimal disruption.If you' re looking for a way to keep your operations flowing while optimizing your pipeline network, hot tapping might just be the answer you've been searching for

To know more Click HereHRSG Pressure Wave & Chemical Cleaning

Power Tech has trained, certified team who can work on removing hazardous waste / chemicals resulting from HRSG pressure wave cleaning process and other process in varied industries

Power Tech along with OEMS have carried Pressure wave blasting procedures for various clients in GCC and also helped in disposing of Sulphur from the HRSG towers with the help of trained team.

To know more Click HereValve Servicing and Calibration

Our Group Company Valve Tech testing and services and Power Tech testing and services specialize in handling services for different type of Valves, Actuators, Pumps, Compressors etc, for more information pls visit www.powertechtesting.com

Aldur-Bahrain

Sand blasting of turbine blades

DEWA, Dubai M station Gas turbine shot blasting by GPTC, NOMAC is our client.

Sea Water Reverse Osmosis(SWRO) membranes Works

Power Tech handles various project with related to Inspection and Replacement of Sea Water Reverse Osmosis (SWRO) membranes

Membrane replacement procedure in brief

- Removal of membranes from the pressure vessel one by one with proper attention and mark each of them with respective pressure vessel KKS number and their respective positions.

- Inspection of the membranes for any physical damages, fouling etc., and verify the condition of the O-Rings & inter connectors

- Weighing of the removed membranes to ascertain the replacement criteria

- Replace it with new membranes based on the replacement criteria

- Provision of personnel , Scaffolding and required tools and tagging for smooth execut

Electrical Maintenance & Commissioning Services

PTD Group has a strong skillset of Engineers and Technicians in the Electrical domain which helps us to offer the below services

- Full plant and facility electrical maintenance services

- HV & LV project works ranging from replacing or upgrading equipment to completely new installations

- Maintenance of HV & LV Distribution Systems

- Preventive Maintenance of Motors, Generators, actuators and breakers

- Overhauling of Turbo Generators

- Switchgear maintenance and cleaning

- Power quality analysis

- PLC maintenance and programming, repair and troubleshooting

- Electrical testing and commissioning, which includes planned preventive and reactive maintenance, testing and commissioning services, and any emergency repairs required

- Conduiting, Cable Laying, Termination and Cable tray works

- Design, Installation and commissioning of various Power projects

MD SIR & GM-UAE

UAE Technical Team-Unit 1

Acid Cleaning of tanks & piping

SHIPCO, Sharjah 1800MW power plant. Acid cleaning of tanks and hydro jetting

Air Intake Filter replacement works

AIF replacement. In mirfa international Power company, Abudhabi

To know more Click HereAll types of AC/HVAC installation and servicing

Installation in Abudhabi, kizad. CCU units